Different colours and shapes of plates!

Different colours and shapes of plates!

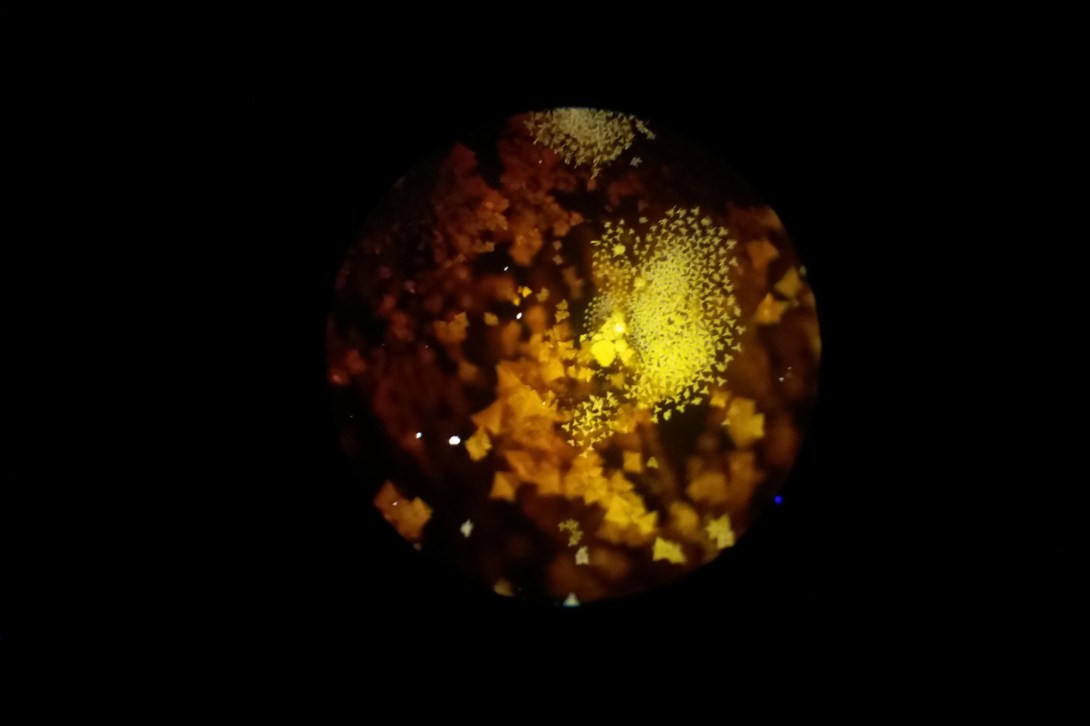

Here are some photos of glazes under microscope. It’s like exploring space.

Living crystal structures captured in time. Microworlds hidden from our eyes. Poetry of nature.

It’s been long time since we posted something on our blog, but today we finaly took some pictures of our latest work. This is what we made with blue, green, white and violet glazes made by David.

Here are some black stoneware pinchpots that we made this winter: bowls in different sizes, mugs and plates with some of our tipical glazes that we developed by ourselves.

We could say this style of pottery is tipical for us, for example we make different variations of Moment mug for a few years now, we actually make them in three different sizes, the smallest is great for black coffee, the medium and large size for white coffee or tea. The handle of this mug is also very special, it takes quite some precise work and skill to make it.

Also tipical is the metal looks that we get with combination of ceramic body and glazes. What else could we say about our black pots? As all of them are made with pinching technique we could say they are sort of primitive but on the other hand they are very thin which makes them elegante and timeless in terms of design. Pinching is one of most ancient techniques of making pottery. Pots are shaped very slowely, completely by hands… pinch, pinch, pinch until you like the shape and make it thin enough. For us this is sort of meditation and is great mental therapy 🙂

Lately we’ve been working on our woodfire kiln. It’s actually a small test kiln inspired by japanese anagama. We fired it for three times, the results were better after every next firing, but the kiln fell a part after the last try, so probably we’ll not be able to fire it again. Anyway our plan for the future is to build a bigger kiln made of bricks.

It’s a special expedition every time we go woodfiring. We go to Kozarisce, where we used to live and where we started with our ceramics. There is David’s grandmothers house in this rural area of Slovenia. Kozarisce is a small village with a big castle surrounded by wast woods. Wild animals live in the woods and also the brown bear. Better not go to far in the woods at night! Ha ha!

It’s a few days project every time we are firing. Preparations have to be made, put the kiln together, make some improvements with the fire place, prepare the pieces and loading. Usually it takes one day. Since we go there together with our daughter, David does most of the “fire work”.

Here are some results of firing, we reached 1230 °C and the total firing time was 24 hours in the first attempt and 28 hours in the last attempt.

This glaze is made of clay that our friend brought from the volcanic island of Madeira. The surface is brownish with spotts and when applied in thin layer it comes out darker, it’s matt and it doesn’t flow at firing temperature of 1250 ºC.

We had quite some unhappy results with the dirt that we picked up in the valley of Završnica. The dirt contains probably a lot of calcium carbonate sands, which makes it very liquid when firing on high temperatures. David applied too much of this limestone sand pieces, because he wanted the glaze to flow. Teapot and mugs sticked to the plate and we couldn’t save them. Teapot and two mugs will be ok for our home use.

Last week we went to Strunjan where salt is still produced in traditional salt pans. Strunjan’s salt pans are actually a part of Sečovlje Salina Nature Park. There we picked up some dirt that we found around salt-fields, so we would use it as glaze. Last year we picked up some dirt in Sečovlje salt pans and use it as glaze which came out great. So we tought the glaze from Strunjan’s dirt will be the same, but actually the Strunjan Salina glaze is completely different. It’s brownish and it gets glossy when applied in thick layer. We like it! And we will use it in the future, maybe we combine it with other glazes as well.

And the results:

With this glaze it’s all about shrinkage trick. Glaze is mostly made out of porcelain and ball clay, so it needs longer soaking time. It’s fired between cone 8 and 9, depends of procentage of the ingredients. During the firing process its shrinkage is bigger than the shrinkage of clay itself. It makes beautiful surface of melted cracks and little craters. Its downside is that it can deform thin objects.

Neverless this glaze is perfect for combining with other colour glossy glazes. It just makes amazing unpredictable effects.

In november 2015 David went to Janja Gora, Croatia to fire some ceramics he made in a special woodfire kiln similar to the japanese anagama. The kiln is named Janjagama. It was David’s long time wish to fire ceramics in a high tempearture wood kiln. Someday he would like to build his own kiln, he already has plans made!

It was a great experience as the people he met there were very nice and hospitable.

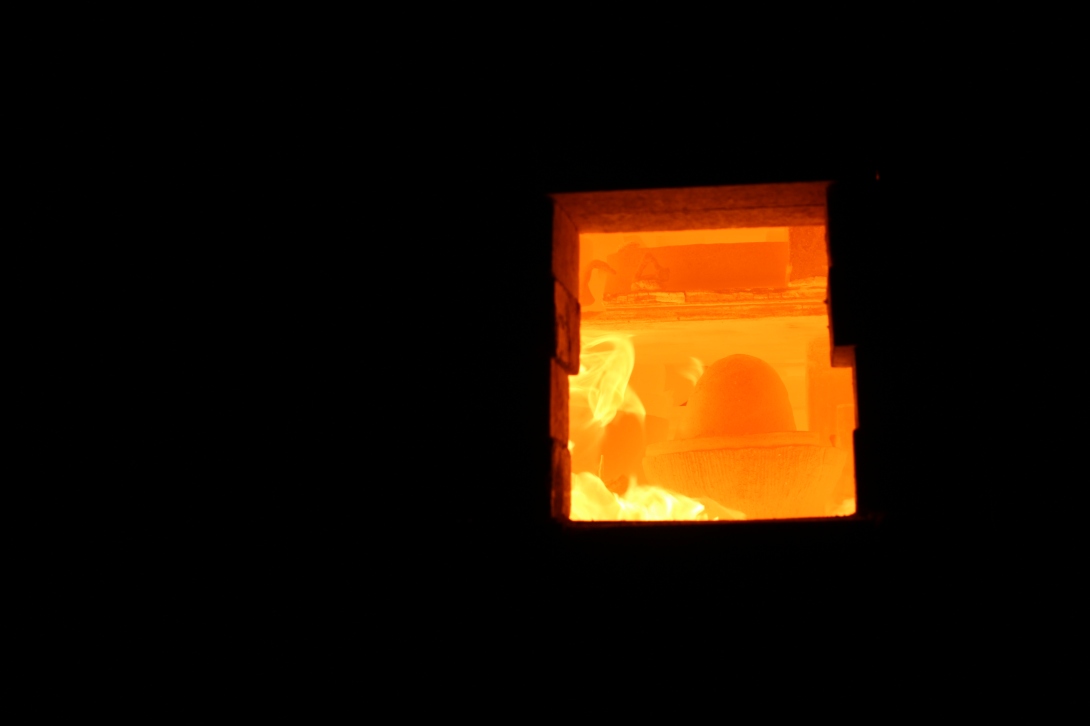

Firing ceramics in this way is very hard work, it takes about two days of loading the kiln with woods to reach temperatures over 1300 °C. And you have to know how much and when to load the kiln. David says you have to listen to the kiln and the winds also and it will tell you when to load woods.

When the final temperature is reached (1311 °C), the kiln has to cool and it takes about one week.

Some pieces didn’t come out as imagined because David made the glazes too strong, so they didn’t melt as expected. But it doesn’t matter, he knows now how to make them just perfect. Some of the pieces that he didn’t like he burned again in our electric kiln.

Some woodfired pieces came out just amazing, we can see “the way of fire”, ashes melted and on some pieces the effects are the result of ashes mixed with glazes that David made.

There are some fotos of the firing process, loading the big Janjagama: